eCommerce: Production Mode Innovation

C2M (Consumer-to-Manufacturer) Model: What It Is and How It Works

C2M means consumer-to-manufacturer, it is a relatively new production mode that originated in China. Now that trending platforms brought it into international markets, C2M has become a buzzword. But what does it mean exactly? Find out here.

Article by Nadine Koutsou-Wehling | August 02, 2024

C2M Model: Key Insights

Originated in China: Since 2015, the consumer-to-manufacturer (C2M) production process has been tested in China. Therefore, all major eCommerce sites in the market use it in one way or another. Temu and Shein have now brought it to international markets.

How C2M Works: C2M connects consumers with manufacturing facilities through technology, hence the name. Items are produced in small quantities to be offered on the eCommerce site, and production volumes are then adjusted to meet real-time consumer demand.

Benefits and Drawbacks: Due to the immediacy of demand and the skipping of steps in the production process, C2M keeps costs and prices down, reduces overstock and turnaround time. But it also means there is little capacity for quality control, resulting in substandard items that are easily discarded rather than returned for repair.

The C2M (consumer-to-manufacturer) model is a widely talked about eCommerce-based production mode. C2M originated in China and is therefore mostly used by online platforms of Chinese origin. But due to its success with consumers, Western platforms are also reorganizing their operations to catch up.

The platforms with the most buzz right now, Shein and Temu, have entered international markets with this strategy. But the C2M model has been proliferating in Chinese eCommerce since its testing phase after 2015. Big names in the market like Pinduoduo, Alibaba, and JD.com have all adopted it in one way or another. And even Amazon is launching its own version soon.

Here is what C2M is all about.

Defining the C2M Model

The C2M model digitally connects online shoppers to the factory. It eliminates the intermediaries typically associated with the manufacturing process, like procurement, warehousing, inventory and order picking. Since all of these steps have costs associated with them, C2M products are significantly cheaper because they skip individual points and cost factors.

Specifically, items are first produced in small test batches to be offered on the eCommerce site. Based on consumer demand, product offerings are increased or discontinued. The manufacturer produces items as they are digitally relayed and ships them directly to the consumer.

The eCommerce platform provides the technology infrastructure and determines branding, design, pricing and packaging. By leveraging big data through AI analytics, providers can predict common patterns and trends in consumer behavior. As a result, product preferences become more accurate.

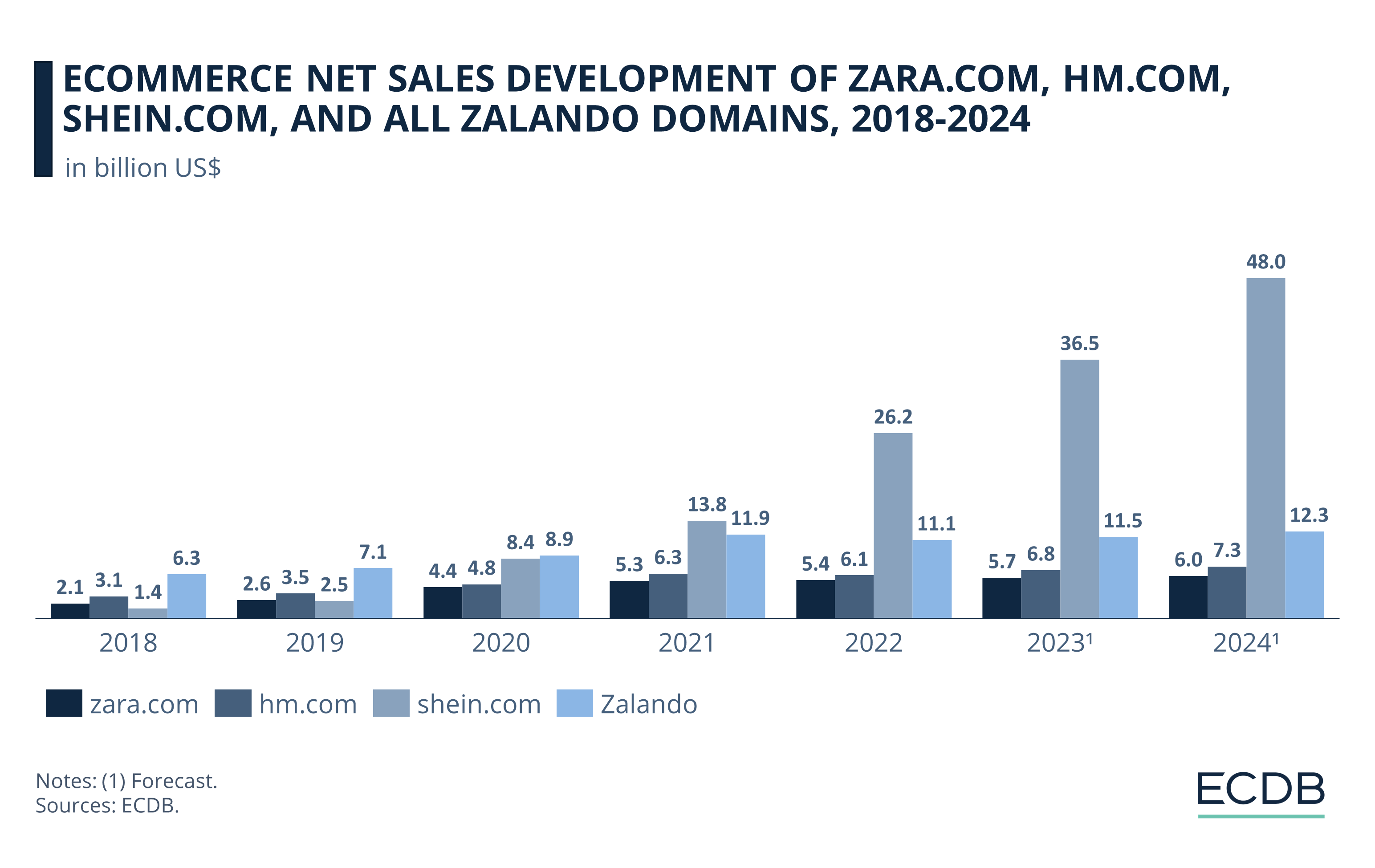

Note how Shein outperformed established fashion retailers in the European market with this model:

Since 2021, Shein has outperformed decades-old established fashion retailers in Europe in terms of annual net sales. As Shein's growth accelerates, it outpaces the others: By 2023, Shein already generated US$36.5 billion in online net sales. Compared to Zalando's US$10.5 billion across all its domains, Shein is taking a clear lead.

So what exactly is it that makes the C2M strategy so successful?

Advantages of the C2M Model

Here are the main features that make this production model stand out from the rest.

Enables Lower Prices: The very nature of C2M reduces costs by eliminating intermediate steps in the production process, which lowers prices.

Reduces Overstock and Waste: In the traditional manufacturing process, a small group of designers determine which products are manufactured. As a result, there was always a hit and miss with consumer demand: The products that no one wanted were left to gather dust in warehouses and eventually destroyed. C2M avoids these pitfalls by more accurately matching the assortment to what consumers want.

Products Reach Markets Quicker: The C2M process is more immediate because it relies on technology. Consumer demand is communicated to manufacturing plants in real time, and because C2M skips most of the middle steps, products are on the way to consumers sooner.

Of course, nothing is flawless, and C2M also has its drawbacks.

Disadvantages of the C2M Model

Here are the problems with C2M.

Lacks Quality Control: Some of the intermediate steps ensure that the condition of products meets quality standards. Skipping these steps also means skipping quality control.

Facilitates the Distribution of Subpar Items That Are Discarded Easily: Low cost and frequent quality problems mean that consumers have little incentive to value products highly. Easy to break, items are discarded as easily as they are purchased. Related to this argument is the fact that returns for repair are not cost effective.

Complex Setup Process: Building a C2M network is expensive and requires a lot of effort and time. Factories, eCommerce providers and the technology must be fine-tuned and integrated for C2M to work seamlessly.

Depending on a company's brand identity, financial resources, and customer base, a C2M production model can be beneficial or detrimental. Certainly, an individual approach tailored to each brand's business strategy and products is the best solution, whether with or without the C2M approach or parts of it.

C2M Model: Closing Remarks

C2M is a new manufacturing model from China that links consumer demand directly to production facilities. Its approach has both advantages and disadvantages, but either way, it is certainly a manufacturing process of the future. Because it solves many of the problems associated with traditional manufacturing, C2M is being widely adopted by established retailers who see the benefits for themselves.

But C2M’s drawbacks should not be underestimated. It is not a one-size-fits-all approach, especially since it requires a lot of resources to set up. Nevertheless, derivatives of C2M are highly likely, considering how much eCommerce has evolved in recent years.

More Insights? We keep our rankings up to date with the latest data, offering you valuable information to improve your business. Want to know which stores and companies are leading the way in eCommerce? Which categories are achieving the highest sales? Check out our rankings for companies, stores, and marketplaces. Stay one step ahead with ECDB.

Sources: Daxue Consulting – FAZ – Substack

FAQ: C2M Model

What is a C2M model?

The C2M (consumer-to-manufacturer) model digitally connects consumers with manufacturers, bypassing intermediaries. Items are produced in small batches based on real-time consumer demand, which reduces costs and speeds up delivery. eCommerce platforms Shein and Temu brought it to international markets, but it has been introduced in Chinese eCommerce in 2015.

What does C2M mean?

C2M stands for "consumer-to-manufacturer." It is a model where consumers are directly connected to manufacturers through technology, bypassing intermediaries and allowing products to be produced and adjusted based on real-time consumer demand.

How does C2M work?

C2M works by digitally linking consumers to manufacturers. It eliminates intermediaries like procurement and warehousing. Products are initially produced in small test batches and offered on eCommerce sites. Based on real-time consumer demand, production volumes are adjusted. The eCommerce platform provides the technology infrastructure, manages branding, design, pricing, and packaging, and uses data analytics to predict consumer preferences and trends. This results in lower costs and faster delivery to consumers.

What are the benefits of C2M?

The benefits of the C2M model include lower prices due to the elimination of intermediaries, reduced overstock and waste as production matches real-time consumer demand, and quicker market reach since it skips steps in the logistics chain.

Click here for

more relevant insights from

our partner Mastercard.

Related insights

Deep Dive

Which eCommerce Company Is Dominating Cross-Border Activities?

Which eCommerce Company Is Dominating Cross-Border Activities?

Deep Dive

Struggle in Top 10 U.S. Marketplace Ranking Most Intense in Lower Spots

Struggle in Top 10 U.S. Marketplace Ranking Most Intense in Lower Spots

Deep Dive

ByteDance Is Big on Personal Care, Powered by Content on Douyin and TikTok Shop

ByteDance Is Big on Personal Care, Powered by Content on Douyin and TikTok Shop

Deep Dive

eCommerce Payments in China: Alipay, WeChat & Top Payment Methods

eCommerce Payments in China: Alipay, WeChat & Top Payment Methods

Deep Dive

Top eCommerce Companies by Market Cap 2024

Top eCommerce Companies by Market Cap 2024

Back to main topics